How Sabae’s glasses are made

There are two types of glasses: metal frame and a cell (resin) frame, and both are completed through about 200 processes. Each of those processes are based on the division of work by specialized factories and craftsmen.

The frames are made of titanium, nickel alloys and precious metals. The number of processes per a piece is about 200, and the leadtime for mass production is five months.

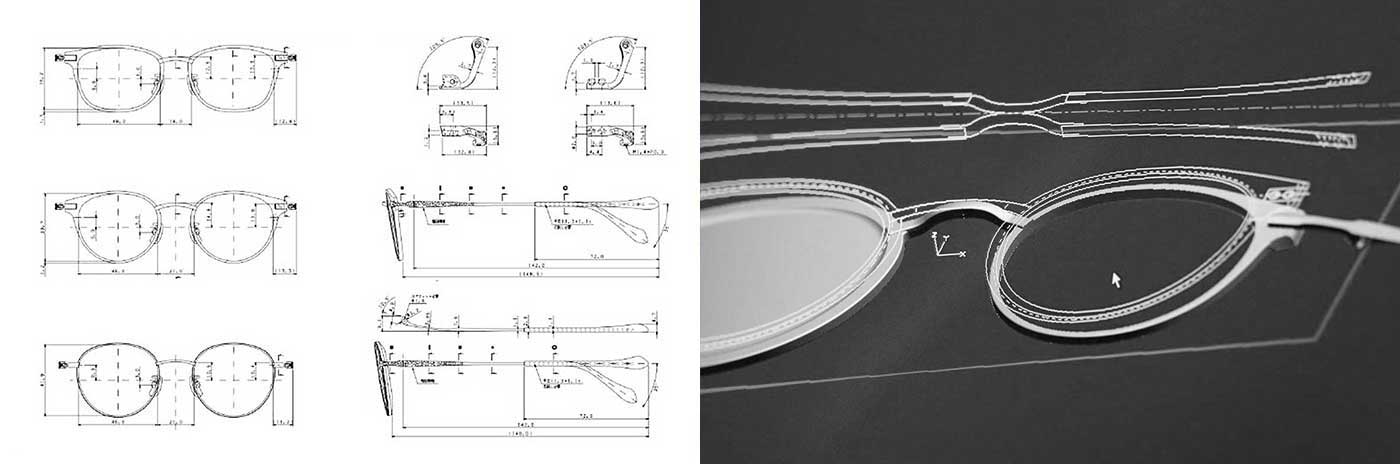

Precise finished product prediction by 3D design

We give shape to various ideas while considering functionality, durability and trends changed along with period. UMEBACHI has adopted a three-dimensional design system exclusively for eyeglasses. Comparing with conventional 2D design, it is possible to predict finished products more precisely.

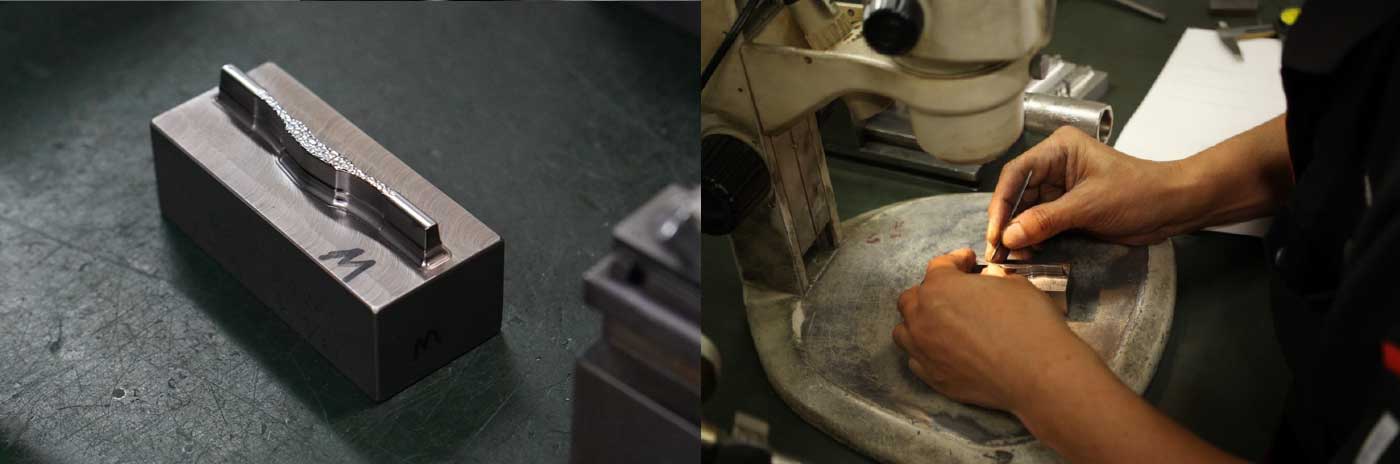

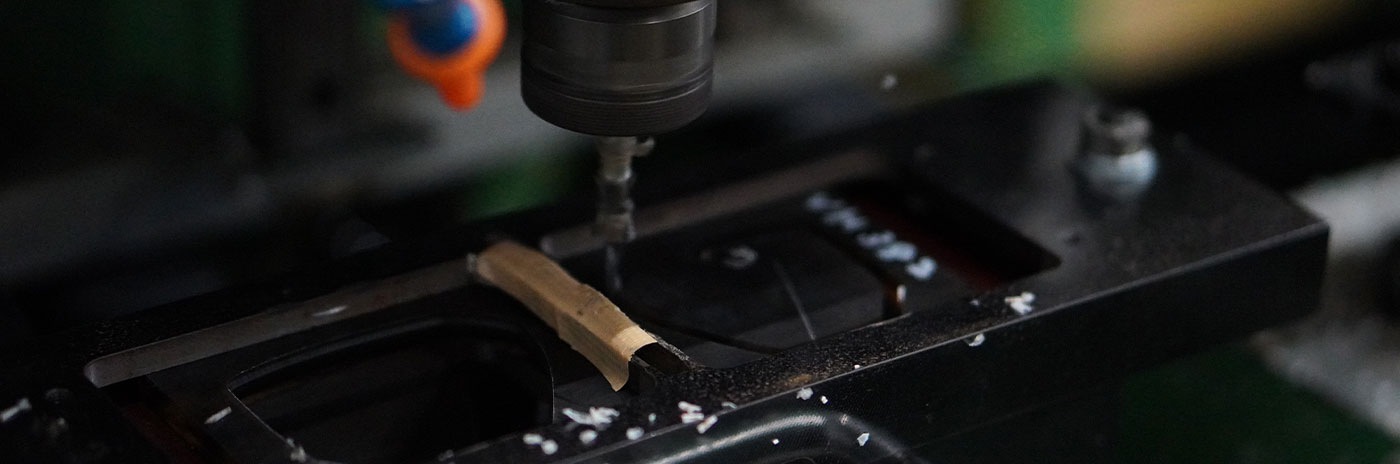

Expression of fine shapes and patterns

Using a large machining equipment, we express fine shapes and patterns that are particular about accuracy by 0.01mm. Multiple molds are required for one model number. The precision of manufacturing is top class among all industrial products.

Finishing by skilled craftsmen

Finishing is conducted by skilled craftsmen to express delicate shapes that cannot be automated. This process of applying our passion for design to the mold (master mold) greatly affects the texture of the product.

Sabae's glasses technology is known as the best in the world

Cold forging is a manufacturing method to make shape while deforming metal by pressing the material at room temperature without applying heat. A round wire of titanium and other is stretched while being beaten, and made into a shape which can be pressed while exhibiting springiness. Sabae's spectacle technology has come to be known as the world's best for processing titanium, which is a difficult-to-process metal.

For making a single part

Each part is manufactured by pressing with a mold that was created to make only one part. Multiple molds are used many times to make one part, and the part is gradually completed. In order to keep the suppleness of titanium, there are many processes to ensure high quality, such as adding heat treatment on the way.

Time and effort put into one part

After pressing, secondary processing is performed to complete the parts. The process of removing burrs caused by pressing and polishing (Called “Mizu-Gara”) gives a deep impression for time and effort put into a single part.

Every single handcraft by skilled craftsmen

The collected finished parts are welded (brazed). We carefully identify the difference in material /size /thickness and joint them while controlling the optimum temperature. Each one is handcrafted by skilled craftsmen.

Assembly and inspection

Craftsmen assemble the front and temples before the polishing process and also check that quality of assembly.

Continuous polishing for about 3 days

Place the frame and polishing material together in a large scrap machine and keep rotating it for about 3 days. The material types and mixing rate of abrasives are know-how that each facility has cultivated independently over many years.

Careful work unique to Japan

The rotating felt fabric with abrasives makes frame polish and luster. Craftsmen thoroughly put their mind of careful work to the details unique to Japan.

Key process for frame durability

Plating and painting are key processes which dramatically improve the durability of the frame and provide a texture and design suitable for eyeglasses worn on the face.

Reliably, carefully and quickly by hand

Attachment parts such as pads, ends and lenses are assembled manually by hand.

The frames are made of wood fiber resin (acetate, celluloid) which is gentle on the skin. The number of processes per a piece is about 100 to 150, and the leadtime for mass production is three months

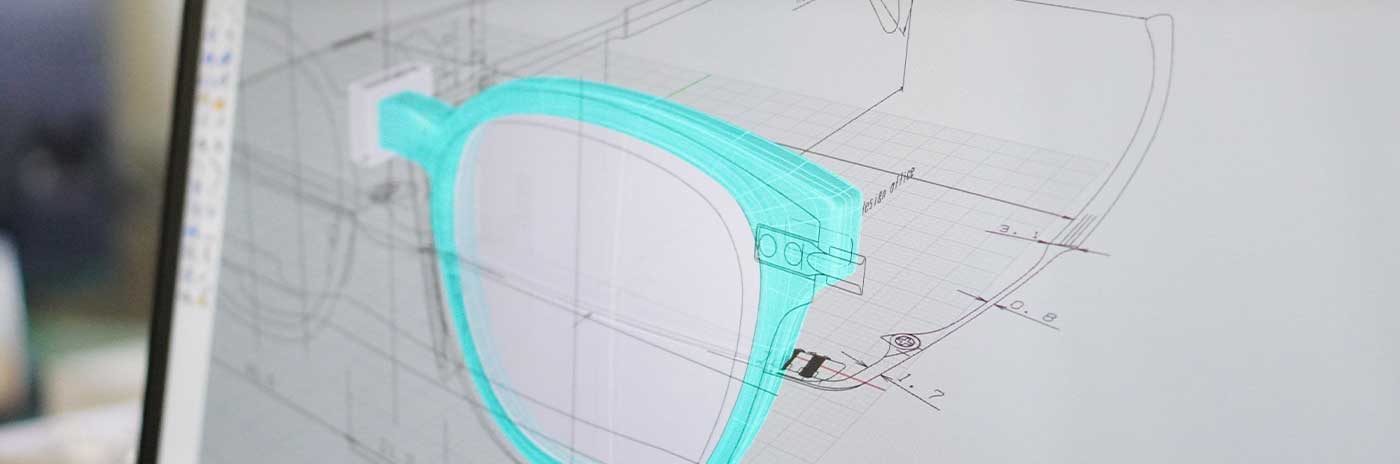

Precise finished product prediction by 3D design

We give shape to various ideas while considering functionality, durability and trends changed along with period. UMEBACHI has adopted a three-dimensional design system exclusively for eyeglasses. Comparing with conventional 2D design, it is possible to predict finished products more precisely.

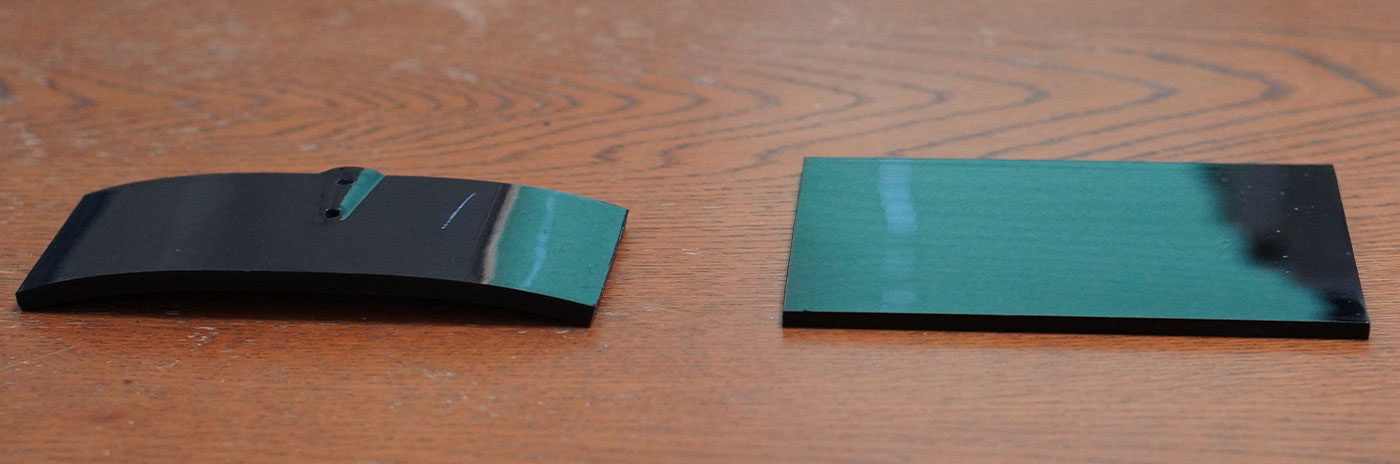

Acetate resin into three-dimensional curved shape

Heat treatment is applied to the plate-shaped acetate resin as the material, and it is pressed to form a three-dimensional curved shape.

Precision cutting by machine control

Acetate resin material is precisely cut by machine control that reproduces the design. Because of the high precision required, a large number of cuts cannot be made in a short period of time.

Craftsmanship with a thorough knowledge of the material's characteristics

The nose pad is welded to the front section. The skill of the craftsman who knows the characteristics of the material shines through.

Delicate and skillful technique

This is the process of adjusting the joint with a rotating file while sensing the balance between the left and right sides and the slightest thickness. This process requires delicate and skillful techniques.

Technology gives you a different look.

The frame and abrasives are placed in a large gala machine and kept turning. The type & combination of abrasives is the know-how that each company has cultivated independently over the years. The texture after polishing is a finish that looks different from what it was before.

Handcraftsmanship reproduces delicate roundness and corners

We reproduce the delicate roundness and corners that cannot be polished by a barrel. We also remove scratches left on the surface.

The delicacy of craftsmanship that cannot be redone

Metal hinges are embedded in the resin front. This is one process that cannot be redone, and shows the delicate nerves of the craftsmen in charge.

Beautifully matched mating finish

The excess portion is cut off at the joint of the front and temples. The beautifully aligned joint finish is one of the specialties of our craftsmanship.

That's why they are called handmade

The joints of the front and temples are finished with a stick file so that there are no steps and they are flat. This is the reason why acetate frames are called handmade.

Deep and luxurious luster

Each product is carefully finished with a soft buff (feather cloth) while carefully assessing the different conditions of each product. Removes fine scratches and creates a deep and luxurious luster.

Final adjustments made by hand

Engraving of brand name, size, etc. This process is also done by hand. The frames are inspected and adjusted before shipping. Sabae frames are well adjusted in every part, and are highly regarded as being comfortable to wear even before fitting adjustments are made.